Technical information

View certificates

Technical information

-

Quality criteria

-

IP product catalog

-

Pal product catalog

-

Construction guide

Introduction : Today, pre-insulated ducts are used in air transmission systems in most large projects around the world, and air conditioning consultants suggest this product as a suitable alternative to traditional galvanized ducts in projects. Considering the importance of air transmission systems in the building as the vital artery of air conditioning systems, in this article we intend to examine the reasons for the success of this product, the ambiguities that are sometimes raised and the criteria that are needed to determine its quality separately.

Why pre-insulated duct : This type of duct is a new product compared to galvanized ducts. Nevertheless, this product has been able to find a place worthy of attention in the ventilation industry, the reasons for which can be mentioned below.

Thermal insulation : Insulation is the main method to prevent energy loss in air transmission ducts. In traditional galvanized ducts, the use of glass wool or stone wool insulation creates many problems in terms of fire and health risks during construction and implementation. Also, the use of elastomeric insulation is also due to the large side surface of air ducts and high cost. Such insulators are not affordable. In pre-insulated ducts, polyurethane or phenolic compressed foam is used, which is free of any CFC, HCFC and toxic substances and is environmentally friendly, which has a very low heat transfer coefficient, uniform insulation coverage on the entire surface of the duct, resistance It is one of the unique features of this material against moisture and water vapor and use in a very high temperature range.

Air sealing : Preventing air leakage along the path of the air ducts is an effective factor to prevent the waste of energy spent in preparing and transporting ventilated air. According to the construction of galvanized ducts and also the connection of the parts of these types of ducts, the air leakage is always more than the standard limit. Meanwhile, the uniform structure of pre-insulated ducts and the use of three types of special adhesives during construction and tight connections with special flanges provide a very high reliability factor for air sealing for pressures up to 2000 pascal.

Indoor air quality : the path of air transmission must always be free of any pollution. Galvanized ducts are always a suitable environment for the growth of bacteria, fungi and contamination due to the type of galvanized materials and also the adhesives used in insulation. At the same time, the minimum aluminum cover and the quality of the special adhesives used in the pre-insulated ducts create optimal air inside the duct and it is a suitable product for use in clean rooms, hospitals and laboratories.

Resistance to water vapor and condensation : water vapor in the air is always distilled on the external surface of the air ducts in the summer due to the temperature difference on the sides of the duct and the dew point temperature of the air. The contact of water vapor with the insulation of galvanized ducts causes the loss of the insulation property and the creation of mold and fungus, as well as the failure of the false ceiling, due to the separation of the insulation and the duct itself, parts of the duct are always exposed to the ambient air, and from this The above phenomenon is inevitable. In pre-insulated ducts, due to the waterproof combination of insulation and the integrated structure of this type of duct (one layer of foam and two layers of aluminum coating), it completely eliminates the problem of water distillation.

Speed of implementation : In galvanized ducts, implementation is done in two phases: construction and installation of the duct and the insulation phase, each of which takes a significant amount of time. Therefore, the implementation costs are high due to spending more time and labor. In the case of pre-insulated ducts, due to the fact that there is no insulation phase, the construction and installation of the duct is much faster.

Sound insulation, resistance to UV rays, longevity and durability can be mentioned among other advantages of this type of duct, which has played a significant role in the success of this type of product in the air conditioning industry.

Ambiguities raised in pre-insulated ducts : In this product, there are some very important points that are one of the strengths in its efficiency and performance in air transmission systems. Sometimes there are issues that cause ambiguity. is Fire resistance, density and malleability are among the most important of them, explanations about clarifying the issue as well as the criteria for diagnosing the quality of pre-insulated ducts are provided below.

Fire resistance : Based on studies and research, the materials used in the construction of structural elements of a building such as walls, floors, ceilings, beams and main columns must be fire resistant. . The materials that are used in other parts of the building such as pipes, ducts, cables, etc. must be in accordance with the international standards of smoke and fire emission and all aspects must be taken into account in terms of safety. In case of fire The fire resistance of materials is checked from three points of view, taking into account the time element as follows: These three items, which are called REI for short, determine the resistance of a material to fire. In general, any material with REI >15 is considered fire resistant, and this number is the lowest duration of resistance of one of the three items mentioned in minutes. The lowest number among the three items I, E and R specifies the REI standard. For example, a material with E=60, I=30 and R=60, according to this standard, is fire resistant for 30 minutes. It is worth mentioning that due to the very high heat transfer coefficient of steel, this number is less than 3 for galvanized sheets. Contrary to popular opinion, it is not fire resistant. Also, regarding the strength and resistance of galvanized ducts, it is important to mention that due to the coefficient of longitudinal and surface expansion during a fire and the moment by moment increase in temperature, these ducts will be opened from their connections and due to their high weight. It causes the destruction of false ceilings and internal walls, which poses a risk to people’s lives and also makes rescue operations more difficult. At the same time, pre-insulated ducts that comply with the fire spread standard “BS476″ parts 6.7 class 0”, due to its very low heat transfer coefficient, it is resistant up to 250 degrees Celsius, and if it is overturned from the joint and supports, due to its very low weight, it will not cause any damage to the false ceiling or internal walls. and it will not cause any danger to the people inside the space and will not cause any problems in the rescue operation.

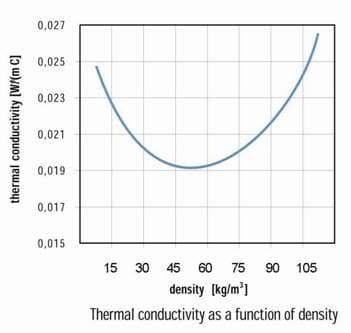

Density and malleability : In the design of pre-insulated ducts, the density factor of foam and malleability of foam and aluminum coating should be considered together and optimally. As shown in the diagram, the optimum density for foam is (45-50 kg/m3), which provides the lowest heat transfer coefficient with the highest flexibility in shaping and forming in that density range. Contrary to what is thought that the stiffer material of the foam has a higher quality, this point should be taken into account. had

Also, in relation to the aluminum coating used on the sides of this product, it seems necessary to mention a few points in this regard. The thickness of aluminum is produced in several different thicknesses according to different uses, and the thicker it is, the stronger it is. On the other hand, the reason for using aluminum in the outer layer of this product is its resistance to rust and corrosion, and the purity of aluminum plays a decisive role in this regard. For this reason, in the comparison of two sheet samples with the same thickness of aluminum coating, if a difference in its hardness is observed, it is due to the presence of alloys and other impure materials in the sheet coating, which causes rust and corrosion against moisture.

Criteria for identifying the quality of pre-insulated ducts : With the explanations given, there is no doubt that identifying the quality of these types of sheets by touching them with your hands is a wrong method. Recently, some companies have started producing and distributing this product, which were only looking for their short-term benefits and profits, and the quality was the last concern of these producers. Therefore, by using these products in projects, not only the benefits have not been used, but in some cases, it has led to many problems in the work process. Problems such as fire, production of toxic smoke and lack of flexibility and malleability and lack of resistance to moisture, which are all key issues in an air duct system. Therefore, in diagnosing the quality of this product, taking into account all the points mentioned in this article, a more accurate criterion should be used.

The best solution in this regard is valid certificates from competent international institutions that can prove the quality of a product. Institutions such as Under Laboratories USA, Warringtone Fire UK, which perform tests at the highest level based on valid standards in this field such as NFPA, ASHRAE, ASTM, BS.

The minimum certificates that a quality product must have are :

Fire spread certificate conforming to standard

& A Class 0 BS 476 part 6

Surface flame spread and smoke emission certificate conforming to

UL 723, BS EN 13823, EN 13501, BS476 part 7, ASTM E-84, NFPA 255, UL 723, BS 6401, NFP92-501, NFPA 90A, NFPA101

certificate of thermal and thermal transfer coefficient Conforming to

ASTM C518, ASTM D1622 standard

Toxicity index certificate conforming to

NES 713 standard, IMO Resolution MSC 61(67),

Compressive strength certificate conforming to

ASTM D1621 standard

Sound absorption property conforming to

BS 2750 standard

Mushroom growth resistance certificate conforming to

ASTM G21 standard

Summary: Pre-insulated ducts have found a special place in the air conditioning industry due to its significant advantages and benefits in air transfer systems. is In the meantime, you should pay attention to important points to ensure the quality of this product, to get satisfaction from its use. The mentioned international valid certificates can be considered as reliable sources in determining the quality of pre-insulated ducts. Also, regarding the quality of pre-insulated ducts, it is important to mention that this operation is performed by trained people under the supervision of factory experts and in accordance with the construction, installation and implementation standards in this field such as DW 144 standard.